|

|

|

BLACK MASTERBATCH | WHITE MASTERBATCH | COLOR MASTERBATCH | FUNCTIONAL MASTERBATCH

MASTERBATCH FOR BAND & POWDER | MASTERBATCH FOR INJECTION MOLD | MASTERBATCH FOR YARN

MASTERBATCH FOR PIPE | MASTERBATCH FOR SHEET | MASTERBATCH FOR FILM | MASTERBATCH FOR FOAM

|

|

|

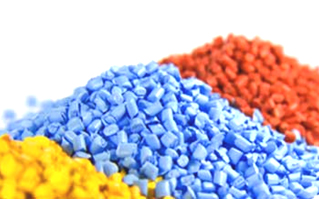

Arirang Chemical goes hand in hand with plastics industries and processing operations as a leading supplier of color masterbatch

in granule, dry blend and liquid form.

Utilizing our innovative chemical know-how and technological strength, we provide a wide range of standard and tailor-made high-performance wp-content/themes/loc/images for a variety of applications: automotive, packaging, construction, household, fibers, sports & leisure etc.

|

|

|

|

Black Masterbatch

| Grade |

Carrier |

Carbon Black content (%) |

Application |

| MBK-716 |

LD + LLDPE |

35 |

Film, Injection |

| MBK-750 |

LD + LLDPE |

40 |

Film, Injection, Extrusion, General purpose |

| MBK-751 |

LD + HDPE |

26 |

Injecton, Blow film, Economic grade |

| MBK-752 |

LDPE |

30 |

High dispersion,Shopping bag, High end quality |

| MBK-722 |

LDPE |

35 |

Yarn, Injection, Woven bag, Agricultural film, Foam, Lamination, Sheet |

| MBK-763 |

PE + PP |

28 |

Yarn, Injection, Woven bag |

|

| |

|

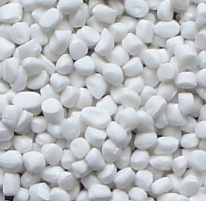

White Masterbatch

| Grade |

Carrier |

Tio2 Contents (%) |

Application |

Characteristics |

| MWD-1501 |

PE |

50 |

Shopping bag |

Anatase type |

| MWD-1601 |

PE |

60 |

Shopping bag |

Anatase type |

| MWD-1701 |

PE |

70 |

Shopping bag |

Anatase type, High Concentration |

| MWD-1502 |

PE |

50 |

Film |

Rutile type |

| MWD1602 |

PE |

60 |

Film ,General purpose |

Good dispersion, Rutile |

| MWD-1702 |

PE |

70 |

Film, High quality |

Twin 2EX, Good dispersion, Rutile |

| MWD-1401 |

PET |

40 |

PET Bottle |

Rutile |

| MWD-1503 |

PE |

50 |

PP Woven bag |

Twin 2EX, Good dispersion

Anatase & Rutile |

| MWD-1603 |

PE |

60 |

T-die, PE & PP Lamination Coating |

Twin 2EX, Good dispersion

Rutile |

| MWP-1601 |

PP |

60 |

T-die, PP lamination Coating |

Twin 2EX, Excellent dispersion

Minium 14㎛ Coating Available, Rutile |

|

| |

|

| Color Masterbatch |

Application & Carrier resin compare table

Application

Carrier resin |

Film |

Injection Moulding |

Blow Moulding |

Extrusion Coating |

Spin dyeing |

Raffia |

Crate |

Cable |

| LDPE |

O |

O |

O |

O |

O |

O |

O |

O |

| HDPE |

|

O |

O |

|

|

|

O |

|

| LLDPE |

O |

O |

O |

O |

O |

O |

|

|

| PP |

O |

O |

O |

O |

O |

O |

|

|

| ABS, SAN, PS |

|

O |

|

O |

|

|

|

|

| PET |

O |

O |

O |

O |

|

|

|

|

|

|

|

Application with Carrier resin table

| Application |

Carrier resin |

Usage(%) |

Appiication |

Characteristics |

| Film |

PE, PP |

3~10 |

Industrial, Lamination

agricultural, CPP, OPP |

High dispersion, Low neck-in

Thermal stability |

| Injection |

PE, PP, PS, ABS |

1~5 |

Food packing, Bottle cap

Automobile, Household, Crates |

Flowablity |

| Blow |

Moulding |

PE, PP, PET |

1~5 |

Cosmetics container

Bottle, Stadium chair |

Flowability, Highstiffness

Smooth surface |

| Film |

PE, PP |

1~5 |

Shopping bag |

Good bubble stability |

| Extrusion |

PE, PP, PS, PET |

1~5 |

Sheet, Pipe, Band, Tube

Corrugated box |

Good heat sealing, Flowability |

| Coating / Lamination |

PE |

3~6 |

Tarpaulin, flexible packaging |

High dispersion, Heat sealing

Thermal stability, adhesiveess |

| Cable |

PE |

2~5 |

Cables |

Processability

Excellent electric properties |

| Foam |

EVA, PE |

1~5 |

Automobile, Packing,

General foam |

Flowability, High stiffness

Smooth surface |

| Yarn |

PE, PP |

1~5 |

Rope, fishing net

non woven bag, Carpet |

High strength, good dispersion |

|

|

|

|

| Functional Masterbatch |

UV Stabilizer Masterbatch

Exposure to sunlight and some artificial lights can have adverse effects on the useful life of plastic wp-content/themes/loc/images because UV radiation can break down the chemical bonds in a polymer. It ultimately causes cracking, chalking, color changes and the loss of physical properties.To counteract the damaging effect of UV light, Arirang UV masterbatch is used to solve the degradation problems associated with exposure to sunlight.

| Name |

Carrier |

TiO2 Contents (%) |

Application |

Characteristics |

| MUD-0101 |

PE |

15 |

Injection, film, exrusion, cable, outdoor plastic |

UV Stabilizer |

| MUP-0201 |

PP |

20 |

PP lope, injection |

UV Stabilizer |

|

|

|

UV Absorber Masterbatch

| The Arirang UV absorber Masterbatch has conjugated organic systems which “absorb” UV radiation due to the double bonds within the molecules absorbing light energy in the UV region and re-emitting it in the IR region. These systems have the advantage that UV absorber can be used to protect whatever is being covered by the treated polymer as well as the polymer itself. |

|

|

|

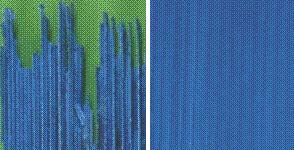

Anti Die Build up Masterbatch

| Excessive die lip build-up has been an issue in the extrusion processes of blown film, fiber spinning, extrusion coating, blow molding, and wire and cable coating. Arirang’s Anti Die Build up Masterbatch removes the unwanted accumulation of material on the open face of extrusion dies, hence improves both the aesthetic quality and the properties of a product. |

|

|

|

Anti-Blocking Masterbatch

| The use of an antiblocking agent added masterbatch creates space between two plastic layers (surface roughness) preventing so-called blocking. Mostly anti-blocking agents are used in multilayer structure films in order to have the highest benefit. |

|

|

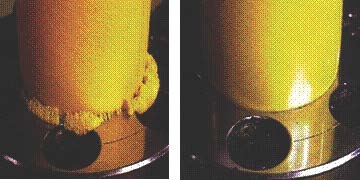

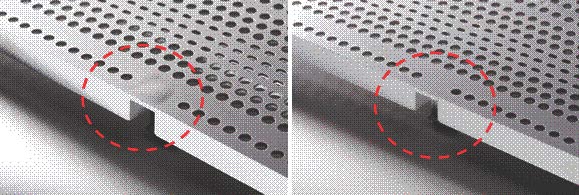

Transparent Nucleating Masterbatch

| This, so-called clarifiers, provide for accumulation of especially homogeneous and microcrystalline structures, so that in case of light absorption through thin finished parts there is no light scattering and consequently the transparency and surface brilliance are significantly increased. |

|

|

| Before |

After |

|

|

|

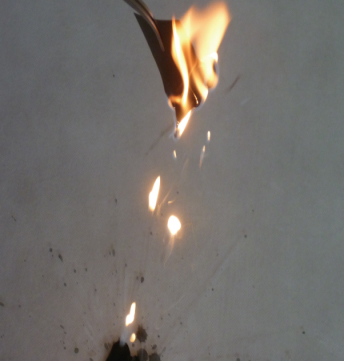

Flame Retardant Masterbatch

The primary goal of this masterbatch is to delay the ignition and burning of materials, allowing people more time to escape the affected area. A secondary consideration is to limit property damage.

Flame retardants masterbatches are applicable to homes and office buildings, cars and mass transit vehicles, furnishings, fibers, household appliances, and many other areas. |

|

|

| Before |

After |

|

|

|

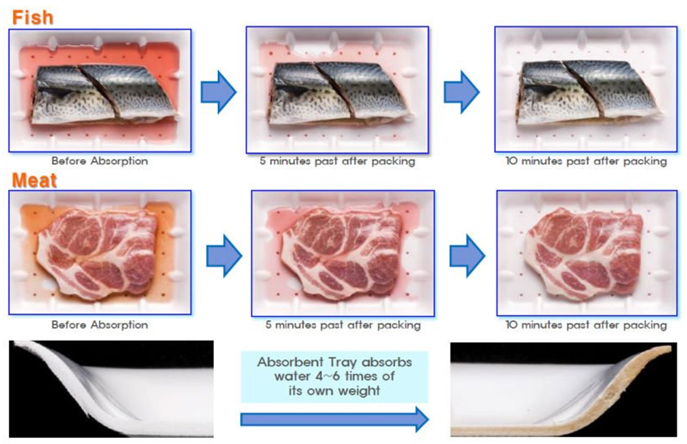

Absorbent Masterbatch

| Polystyrene combined with absorbent additives can effectively absorb water/bleed water from meat and fish which cause spoilage of the product. This masterbatch helps to keep the freshness of the product and the value of the foods for long time by removing leaking juice from meats and fish through specially constructed structure to absorb water. |

|

| Awarded KITECH President Prize in KOREA STAR AWARDS 2011 |

|

|

|

Odor Absorber Masterbatch

| By binding malodor components, Arirang Odor Absorber Masterbatch can reduce malodor significantly while compatible to polyolefines and technical polymers. |

|

|

|

Nucleating Agent (Talc) Masterbatch

| Grade |

Carrier |

Tio2 Contents (%) |

Application |

Characteristics |

| MCD-0501 |

PE |

50 |

Foam sheet |

Good dispersion,adding Tio2 |

| MCD-0601 |

PE |

60 |

Foam sheet |

Good dispersion,adding Tio2 |

|

|

|

Calpet

| Grade |

Carrier |

Tio2 Contents (%) |

Application |

Characteristics |

| AC-800 |

PE |

80 |

Film, Injection

shopping bag |

Good dispersion |

| AC-801 |

PE |

80 |

Film, High quality |

Good dispersion, 2micron |

|

|

|

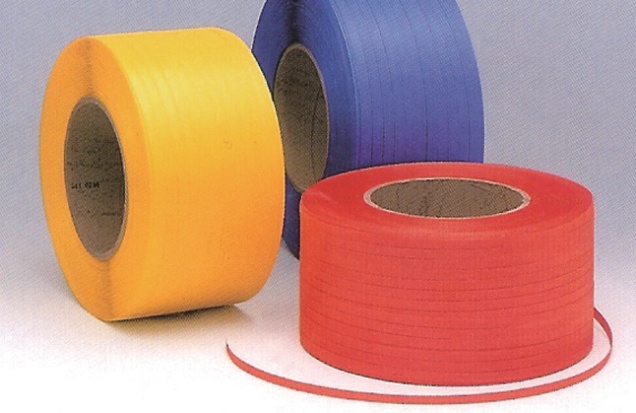

| Masterbatch for Band & Powder |

PP Band

PET Bands

Foamed Bands

SR Yarns

Binder Yarns

PE Powder

PA Powder |

|

|

|

|

| Masterbatch for Injection Mold |

Foods

Household Items

Industrial Items

Home Appliances

Automobile Pallets

Stationary

Civil Works |

|

|

|

|

| Masterbatch for Yarn |

Filament

Tarpaulin

Rope

PP Burlap Bags

PET

PA

Industrial Purpose

Household Items |

|

|

|

|

| Masterbatch for Blow |

Foods Containers

Industrial Containers

Agricultural Containers

Cosmetics

Multilayer Containers

Tubes |

|

|

|

|

| Masterbatch for Pipe |

Waterworks

Drain Pipes

Fiber Optic Cables

Gas Pipes

Conduit Tubes

Marine Structures

Pipes for Gas & Oil |

|

|

|

|

| Masterbatch for Sheet |

Foods

Water proof Sheets

Agricultural Sheets

Interior Items

Vehicle Items

Stationary

ABS Sheets

PC Sheets |

|

|

|

|

| Masterbatch for Film |

PE Blow Film

PE Cast Film

PP Film

PU Film

PS Film

PA Film

PET Film

Hot Melt Film |

|

|

|

|

| Masterbatch for Foam |

PE Crosslinking

PE Non-Crosslinking

PP Foaming

PS Tray Foaming

XPS Foaming

PVC Foaming

EVA Foaming

PU Foaming |

|

|

|

|

|

|

|

|